Q. How can a gasket be designed to provide long-term sealability, as required in

an HF Acid Unit?

A. By focusing on the gasket seating stress. All sealing depends on gasket seating

stress. The gasket has to be “squeezed” in order to seal. The amount of gasket

stress developed must be high enough to achieve an initial seal upon installation

- plus additional stress to offset two additional factors: A) long-term relaxation,

and B) Thermally induced load changes.

Q. How does the ALKY-ONE gasket compare to other gaskets in this regard?

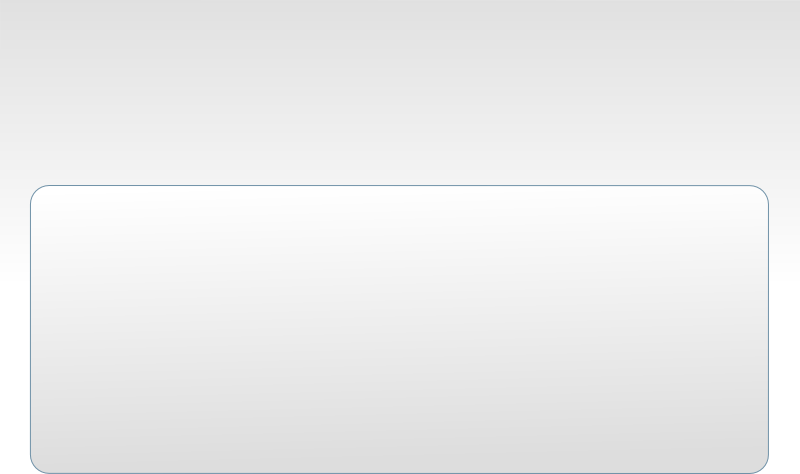

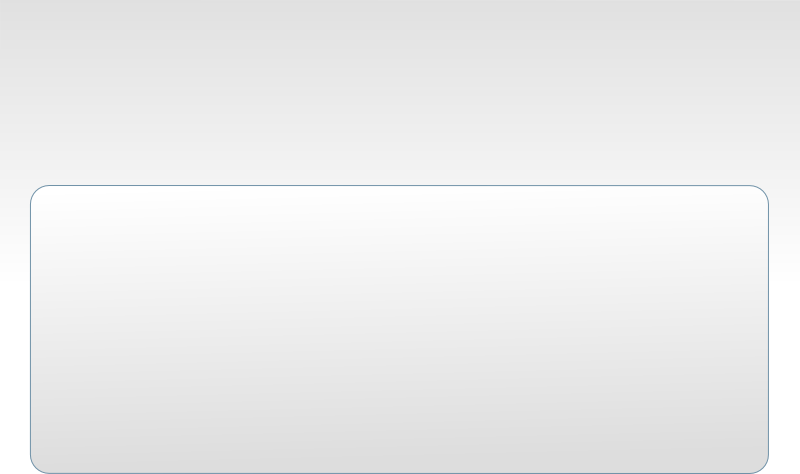

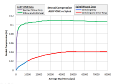

A. As shown in the graphic above (click on the graphic for a larger image), for

the 150# sizes shown, the primary sealing element of the ALKY-ONE gasket develops

an average of more than 3 times the gasket stress as the spiral wound seal on the

other commonly used gaskets. While all gaskets may be able to achieve an initial

seal at start up, it is this additional stress that assures that the ALKY-ONE will

still be sealing tightly years after installation.

“Sealability is

all about

gasket stress.”

Sealability - it’s always important, no matter the flange or application. But in

HF Alky Units, sealability isn’t just important - it’s critical.

Hydrofluoric acid is an essential chemical catalyst in the formation of useful alkylates

from short-chain (gaseous) hydrocarbons. As such, it plays a crucial role in modern

refining processes. The problem? Hydrofluoric acid does not play nice!

HF Acid is one of the most dangerous acids known. It is so lethal that the Centers

for Disease Control lists it as a potential Chemical Terrorism Substance. OSHA limits

exposure to just 3 parts-per-million over an 8-hour shift, while NIOSH classifies

it “Immediately Dangerous to Life or Health” at concentrations of 30 parts-per-million

or higher. It is unique among acids in its ability to pass directly through the

skin to the underlying tissues and bones. Once there, it not only liquefies the

tissues and erodes the bones, but the fluorine anion hijacks the body’s neurochemical

processes, causing a cascading failure of essential systems.

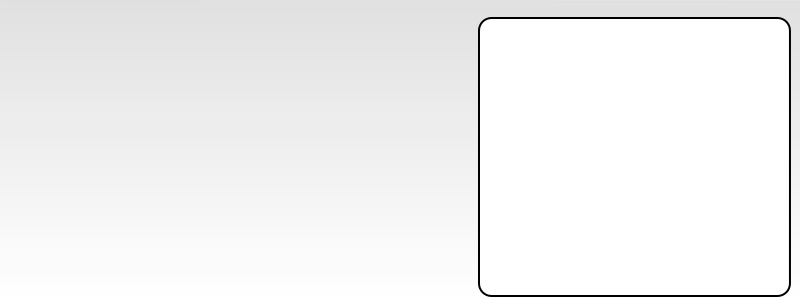

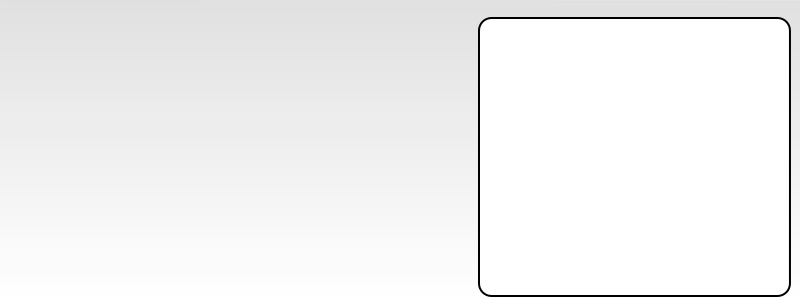

The Flange Assembly Demonstration Unit (FADU) pictured at the right measures and

displays

real-time gasket compression in response to the applied bolt loads, giving

us a peek at the

actual dynamics that occur when a gasket is tightened in a flange.

The FADU allows us to

easily compare the compressive responses of different gaskets

in the same environment to

see which provides the more positive seal under initial

bolt-up conditions.

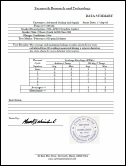

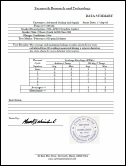

Clicking on the thumbnail to the left will show you one of those

comparisons. The

top line is the compression/load line for the ALKY-ONE

gasket. The bottom line is

the compression/load line for a common

competitive gasket - a spiralwound gasket with

an inner cam-profile ring

with PTFE faces. Take note of the amount of bolt load required

to bring

the gasket to full compression - that point in which the gasket reaches a

flat

line. The ALKY-ONE is fully compressed at about 28,000-psi bolt

load, whereas the competitive gasket requires about 53,000-psi. Since the Yield

Strength of a B7 stud is about 106,000-psi, the ALKY-ONE gasket will come to full

compression at just 26% of yield, whereas the competitive gasket requires almost

50% of yield. Many corporate bolt-up standards use 50% of stud yield as their target

load - barely enough to compress the gasket to a point of stability!

When fully tightened to Chevron’s recommended 120 ft.lb, how much gasket seating

stress do these two gaskets develop? Due to their differing geometries, the results

are astonishing. Here they are:

Our mathematical modeling suggests that at full torque, a 4” 150# spiralwound gasket

with a cam-profile inner ring with PTFE facing materials will develop only 6,447-psi

of seating stress on the spiral winding - well under the industry recommended minimum

of 12,500-psi for sealing spiralwound gaskets.

And the ALKY-ONE? At the same torque it develops 21,784-psi of gasket stress - over

three times as much!

Leak-Free Start Up

You now have the option to choose a gasket designed to start up leak-free! The ALKY-ONE

gasket comes to full compression far before competitive gaskets. At any given torque

it is designed to develop several times the gasket seating stress.

Seals faster… Seals tighter… That’s a pretty easy decision, isn’t it?

Fugitive Emission Control

With an OSHA limitation for HF Acid exposure of just 3-parts-per-million over an

8-hour shift, fugitive emission control is more than just an LDAR buzzword. What

styles of gasket construction can achieve “parts-per-million” sealing? Which can’t?

In our NPRA paper, we discussed recent test information showing that spiralwound

gaskets - made to today’s standards - could not reliably seal below 50 parts-per-million

without contacting the outer guide ring.

In contrast, the KAG style of gasket - the same as used in the ALKY-ONE gasket -

has been tested for fugitive emissions, and has passed that test with an average

leak rate of just 1 part-per-million! The Fugitive Emissions Certificate and Test

Summary are posted here for your review.

It is important to admit that as impressive as these results are, they are only one

aspect of sealing. Comprehensive sealability must also encompass real-world sealability

at start up as well as long-term sealability under typical operating conditions.

In Texas, a prominent HF Service Provider reports that upon unit start up - even

when the gaskets they install in a turnaround come up leak-free - they see major

leaks occurring in flanges they had not serviced.

Leak-free performance is not just a matter of sealing when the gasket is installed.

The gasket must continue to seal month after month, year after year. It must continue

to seal in spite of plant upsets. It must continue to seal regardless of the number

of shutdowns and restarts.